a brief history of candles and candle making

Years ago, I was heavily involved with a living history group called Clann Tartan. They are a group dedicated to teaching others what life was like in early 17th century Scotland. I delved into a number of areas of interest during that time, including candle making. What follows is an educational resource I wrote based on that research and hands-on work I did in coming up with a candle-making demonstration I would do for our events. While this doesn’t quite fit in with what I usually share on this site, I thought it would be a fun little article to post.

I’m setting the post date as February 2, because it is Candlemas. Historically on Candlemas, many Christians would bring their candles to their local church, where they are blessed and then used for the rest of the year; for Christians, these blessed candles serve as a symbol of Jesus Christ, who referred to himself as the Light of the World.

Introduction

Man has always been dependent upon artificial lighting to allow them to work and play past sunset. Electric lighting has only been available for about the last century, leaving candles to play a very important part in the everyday life of man, and the process of making these candles remained relatively unchanged up until the industrial revolution.

My own interest in making candles began after I joined the Scottish Living History group, Clann Tartan. While Clann Tartan is geared towards the portrayal of the military aspects of life in 1630, camp life is an integral part of what is presented.

Candle making became something I wanted to do as a demonstration at our events during those times I needed a diversion from being a pikeman. As part of the research needed to develop a demonstration I needed to know more than just ‘how’, I also needed to know the history that led up to it. The information contained here is a result of that research.

A great many resources were used, both printed and on the web, and I continue to do further research as time permits.

Wax: The fuel source

By its dictionary definition, a candle is any solid mass of wax, tallow or other fatty substance with an embedded wick that is burned to provide light. References to candles can be found dating back to biblical times, and an early example from about the First Century AD was found in France. While the image evoked when discussing candles is often that of a wax pillar or taper candle with a paper or cotton wick, through the ages a variety of substances have been used for both wick and candle material.

Animals of various types have often been the source of light providing materials. Lewis and Clark wrote of a fish called the eulachon and often referred to it as ‘candlefish’. This candlefish, a member of the smelt family, was once highly prized as a seasoning, but when dried they could be burned for light. This particular fish is now primarily found in the Pacific Northwest, but at one time was found in many areas of North America. Other fish found from Greece through Northern Europe, were used in a similar fashion, including the tail fin of the dogfish found in areas near Newfoundland.

Aside from fish, birds such as certain types of penguins, storm petrels, and the great auks of the Shetland Isles would be staked with a wick of dried moss down their throat and lit for light. Often, however, these animals proved too valuable as a food source to be used for light in any widespread fashion.

In the 18th and 19th Centuries, when whaling was at its peak, it was found the fat known as spermaceti provided a brilliant light when burned. In fact, a candle made of spermaceti was used as the original measurement of a unit of light known as a candlepower. Many lighthouses of this period used spermaceti as the fuel for their warning beacons.

Nearly since their origins, the main source of fuel for a candle was the rendered fat from sheep, cattle, or other livestock, otherwise known as tallow. (note: Specific fats from sheep and cattle when rendered are also called suet, and rendered pork fat is the source of lard.) As it was not always desirable to slaughter an animal to obtain the tallow, cooking fats and oils were also collected and saved to be used for both candle and soap making.

Aside from actual candles, splinters of resinous woods, or the peeled and dried core of many common rushes would be dipped in melted tallow to produce a type of candle called the ‘rushlight’. These were very common, especially in poorer households. They did not burn as long as the typical candle but were easier and less time consuming to make. A typical rushlight, about two feet long would burn for up to an hour. To increase the burn time, they were held at an angle either in a split piece of wood or a special metal holder. Some of these holders also combined an actual candle holder for times when the burning of a regular candle was desired. While relatively inexpensive to make or purchase, tallow candles tended to burn rather quickly, and if the tallow was not fully rendered would often give up foul odors and a cloud of sooty smoke. Additionally, candles made from tallow would often be very soft, and hard to store in warm conditions.

Another animal product used for candles that is even prized to this day is beeswax. Cleaned of the honey and other debris, then melted down, beeswax burns much brighter and without the foul smell associated with tallow candles. However, the availability of beeswax made them much more valuable. Common folks who had access to beeswax might mix some in their tallow to help overcome some of the shortcomings of plain tallow.

Under most circumstances, it was only the wealthy or the church that could afford to burn candles that were made from pure beeswax on a regular basis. Possibly due to the association with animal sacrifice, or maybe simply because of the smell, most churches burned nothing but beeswax candles and would often have to seek out endowments to help offset their cost.

In addition to animal products, many plant products contain oils or waxy substances that can be harvested and rendered almost like tallow for candle making. One still in use today is the bayberry found in England and North America. Producing bayberry wax, however, is time-consuming as it takes between eight and eleven pounds of berries to obtain just one pound of wax.

Aside from the rushes and wood splinters used, there does not seem to be much documentation on wicking materials. Most likely it was made from familiar materials that were available; spun flax or hemp in early times to later include cotton and paper materials. It is quite possible that some of the same knowledge used to produce match cord and fuses was also applied to candle wicking.

When a candle burns, it is the wax that provides the fuel, not the wick. As the wax is consumed, if the wick is not shortened accordingly, the flame could potentially grow in size to match the length of the wick. Modern wicks are braided, with one strand pulled much tighter than the rest. This causes the wick to curl in on itself, and as such the end of the wick is burned away in the flame of the candle, keeping the wick at a consistent length. Simple, twisted or spun wicking will not do this, and as such needed to be trimmed, or as it was called then, ‘snuffed’. While this could be done with a knife blade, or even with your fingers, many households that used candles in any number or on a regular basis would have an actual ‘candle snuffer’.

Candle snuffers were a scissors-like device that was used to snip off the ends of the wick, and they often had some specific features regular scissors or snips did not. Many candle snuffers would have an enlarged lip on one of the blades used to catch the cut off pieces of the wick so they would not risk dropping a smoldering piece of wick on something that could potentially catch fire. Most candle snuffers were also made somewhat ornately and would be put in a place of display when not in use. As such, they would also either have a special stand, or even small legs incorporated into the body of the snuffer so they did not have to be placed directly on a surface, risking soiling nice linens.

The Chandler

A chandler is the term used for someone who makes candles and dates back before the thirteenth century when the first formal Chandler guilds were started. Being a chandler became quite the popular profession as shown in the 1292 Paris tax rolls, which listed no fewer than 71 chandlers. Chandlers were grouped into one of two categories depending on if they were a wax chandler or tallow chandler. The English Tallow Chandlers were incorporated in the mid-15th Century and due to the taxes involved, there was a period where it was illegal to make your own candles.

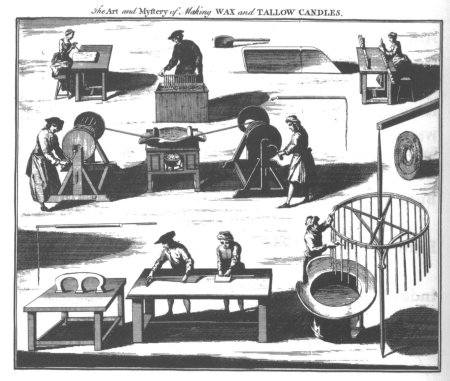

Throughout the centuries, the most basic method of making candles has remained largely unchanged. A wick is repeatedly dipped in the melted wax or tallow, allowing for a brief cooling period between dips. Each dip would add another layer of wax until the candle was of the desired size. While there were some variance and advances, this is the basic method that continued to be used up until the industrial revolution.

While dipping was the primary method of candle making, it is believed the French started doing molded candles on a regular basis. Molds of pewter and wood have been found dating to sometime in the 14th Century. Most molds were made of two halves, which were bound together. Melted wax was then poured into the mold from the base. Once cooled, the blocks would have been separated and the candle removed. Wicks could have been added at this point, or some molds would have held the wick centered in the mold and the candle formed around it. Making molded candles, while giving a more consistent finished product, would be much more time consuming to make as you would have to wait for each candle to cool and be removed from a mold before being able to make another. Another problem would be the wax. Both beeswax and tallow would remain tacky when cooled, more than likely making it difficult at times to remove the candle from the mold.

Because of these shortcomings, even into the 1900s, most people who had to rely on candlelight hand-dipped their candles. Candle making was often a chore done by the children, usually in the fall or other times when an animal was slaughtered since that is when you would have the most tallow available. If a supply of candles would run low, cooking fats could be rendered and more candles or rushlights could be made in smaller batches.

Tallow was a common link in the history of candle making and soap making, for people making their own items, as well as large companies. Proctor & Gamble was originally two separate companies; Gamble a soap maker, and Proctor a chandler. Even at this time, candle making was still a productive business. When Proctor & Gamble joined forces in Cincinnati in the 1840s, there were eighteen other soap and candle makers in that city alone.

It was about this time that the substance stearin was isolated in tallow. It was discovered that by adding a bit extra to tallow, the candles produced would burn brighter, cleaner, and be firmer when hardened; a major advantage in warm climates. In the 1850s paraffin was first refined from petroleum. Paraffin burns brighter than tallow and eventually would be easily produced in large quantities. And since it was easier to release from a mold than beeswax, paraffin candles were soon being mass-produced. With the industrial revolution came machines that would pour, cool and release numerous candles at once, only the poorest or most rural families would continue to make their own candles.

Today candles are viewed more an object of personal enjoyment or seen as an emergency provision. The wide availability of materials has seen a resurgence of candle making as a recreational hobby, not a necessity.

Candles and the 17th Century

In 1630 Scotland, in a military encampment, the beeswax candles that most of us tend to favor would be a treasured rarity. Even for the officers, having beeswax candles would be a rare treat. More common would be tallow candles or various types of oil-based lamps. The tallow to make candles for the officers quite possibly came from the animals slaughtered to feed the soldiers.

When not working by the light of a campfire, the soldiers would rely heavily on rushlights, propped up in a make-shift holder. It would not be a rare thing to see a soldier or camp-follower making them using collected cooking fats. Torches of various sorts would have also been in use by the soldiers around the camp.

It is almost ironic how even though the method behind candle making has not changed much since the time of Gustavus Adolphus, we find ourselves with an abundant supply of beeswax candles for our use, while tallow candles, a staple of the time, are nearly impossible to come by.

Bibliography

The New Encyclopedia Britannica.

Chicago, IL: Encyclopedia Britannica, Inc., 2001

Coney, Norma. The Complete Candlemaker.

Asheville, NC: Lark Books,1997.

Constable, David. Candlemaking: Creative Desiqns and Techniques.

Turnbridge Wells, Kent: Search Press Ltd, 1992.

Oppenheimer, Betty. The Candlemakers’ Companion.

Pownal, VT: Storey Publishing, 1997.